Introducing the UASB tank

UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse flow biological treatment tank through anaerobic sludge bed. UASB is designed for wastewater with high concentrations of organic contaminants and low solids content. The input COD concentration is limited to a minimum of 100 mg/l; If SS > 3000mg/l, it is not suitable for treatment with UASB.

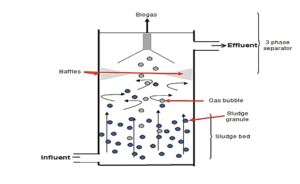

UASB is an anaerobic biological treatment process in which wastewater will be distributed from the bottom up and controlled at an appropriate speed (v < 1 m/h). The structure of a UASB tank normally includes: tank bottom water distribution system, treatment layer and phase separation system.

Wastewater is distributed from the bottom up, through an anaerobic sludge layer, where the process of decomposition of organic matter by microorganisms will take place. The treatment efficiency of the tank is determined by this microbial layer. The phase separation system above the tank is responsible for separating the solid – liquid and gas phases. Here, the gases will fly up and be recovered, the sludge will fall to the bottom of the tank and the treated water will flow through the settling trough. subsequent processing.

Conditions for applying UASB tanks

- Initial culture sludge: minimum concentration is 10 kg VSS/m3. The amount of sludge added should not be more than 60% of the tank volume.

- Organic matter content: COD 50,000 mg/l requires diluting the wastewater or recirculating the output wastewater.

- Nutrients: minimum concentrations of N, P, S elements can be calculated according to the following expression:

(COD/Y) : N : P : S = (50/Y) : 5: 1 :1

Y is the cell yield coefficient depending on the wastewater type. Easily acidified wastewater Y= 0.03, difficult to acidify Y= 0.15.

- Suspended residue content: wastewater with high SS content is not suitable for this model. SS > 3,000 mg/l that is difficult to biodegrade will remain in the tank and will prevent wastewater decomposition.

- Wastewater containing toxins: UASB is not suitable for wastewater with ammonia content > 2,000 mg/l or sulphate content > 500 mg/l. High salt concentrations also have a negative effect on methane bacteria. When the salt concentration is between 5,000 – 15,000 mg/l, it can be considered toxic.

Operating principle of UASB tank

UASB tanks operate based on the following 3 stages:

Phase 1: Hydrolysis and cleavage of macromolecular compounds

At this stage, complex insoluble wastes such as polysaccharides, proteins, lipids are transformed into simpler substances such as sugars, ammonium acids, and fatty acids. This process is transformed by enzymes secreted by biological bacteria.

Stage 2: Acidification

At this stage, the anaerobic tank will undergo fermentation to convert dissolved substances into simpler substances such as fatty acids, lcohols, lactic acid, methanol, CO2, H< sub>2, NH3, H2S and new biomass.

The pH in the tank can be reduced to 4.0 due to the formation of fatty acids.

Stage 3: Methaneification

Here, the substances are methanized into CH4 and CO2 gases. The chemical reaction at this stage is:

CH3COOH -> CH4 + CO2

2 C2H5OH + CO2 -> CH4 + 2 CH3COOH

CO2 + 4 H2 -> CH4 + 2 H2O

Protein hydrolysis: NH3 + HOH -> NH4- + OH-

The OH- gas generated from here will react with CO2 to form bicarbonate ions.

CH4 gas burning equipment on UASB Tank was built and installed by King Power

Customers who need to build and install wastewater treatment systems, please contact Hotline 0917545157

Related articles

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...

Oxidation ditch in wastewater treatment

What is an oxidation ditch? Oxidation ditch is an improved form of complete mixing aeroten...