Rubber wastewater treatment is a mandatory requirement for the rubber processing industry. The rubber industry has had a fairly high growth rate in recent years and brought huge benefits to the Vietnamese economy. However, wastewater from this industry is very difficult to treat, so the cost to treat rubber wastewater is no less than other industries because of the high level of pollution, mainly total nitrogen. and organic substances.

Rubber wastewater treatment system designed by Nam Viet ETC for Customers

Origin of wastewater generation at rubber processing factories

- The process of transporting, storing and processing input raw rubber

- Production and mixing process to create products from sanitary wastewater, cleaning, machine washing…

- The process of cleaning, cleaning, washing machinery and equipment, washing factory floors, production areas….

Hospital staff’s daily activities such as: eating, cleaning, bathing….

Composition and properties of rubber wastewater

- Organic matter, COD, BOD, high color ….

- Nutrients of nitrogen (N), phosphorus (P) are very high

- Suspended solids

- Germs and bacteria that cause disease.

- Organic substances and color in wastewater (about 55-65%) will reduce the amount of dissolved oxygen in the water, affecting the life of aquatic animals and plants.

- Nutrients of N and P cause eutrophication of sources receiving wastewater, affecting living organisms in the aquatic environment.

- Suspended solids cause water turbidity, creating sediment deposits that clog drains, pipes and gutters.

| TT | PARAMETER | UNITS | WATER PUS | PUS |

| 1. | pH | – | 5 – 9 | 6 – 9 |

| 2. | BOD | mg/l | 9,000 – 12,000 | 1,000 – 1,600 |

| 3. | COD | mg/l | 4,500 – 6,000 | 1,500 – 2,100 |

| 4. | Suspended solids | mg/l | 1,000 – 1,200 | 300 – 500 |

| 5. | Total Nitrogen | mg/l | 150 – 300 | 100 – 150 |

| 6. | Nito – NH3 | mg/l | 80 – 120 | 50 – 80 |

| 7. | Total Phosphorus | mg/l | 60 – 120 | 30 – 60 |

Standard column A – QCVN 40:2011/BTNMT

| STT | Target | Unit | Value (QCVN 40 : 2011/BTNMT, Column A ) |

| b | pH | – | 6 – 9 |

| 02 | BOD | mg/l | 30 |

| 03 | TSS | mg/l | 50 |

| 04 | Color | mg/l | 50 |

| 05 | Total Nitrogen | mg/l | 20 |

| 06 | Total Phosphorus | mg/l | 4 |

| 07 | COD | mg/l | 75 |

| 08 | Coliform | MPN/100ml | 3,000 |

Rubber wastewater treatment process

Treatment plan

- Does not make noise, does not cause unpleasant odors to the surrounding area.

- Meet waste discharge standards and reuse water for production processes

- Does not affect the aesthetics and general operations of the factory

- Simple management and operation, reasonable operating costs.

From the above characteristics and the requirements to be achieved after treatment, wastewater treatment technology includes the following main steps:

- Step 1: Use mechanical methods to remove large substances suspended in water and neutralize

- Step 2: Use a 2-step physicochemical method to treat organic substances, COD, N, P, color… of wastewater in the best way

- Step 3: Use anaerobic, anoxic combined aerobic biodegradation method to remove organic substances present in wastewater. Aims to continue to reduce the amount of Nitrogen, Phosphorus and organic pollutant content in water (COD; BOD)

– Step 4: Use disinfection method to kill harmful microorganisms in water,

– Step 5: Use pressure filtration method combined with biological lagoon (if there is a treatment area) to thoroughly treat suspended solids (TSS) and color and iron , and remaining organic substances in wastewater

– Step 6: Biological sludge and physicochemical sludge will be pumped to the biological and physicochemical sludge tanks and then pumped to the sludge press (if any) for treatment.

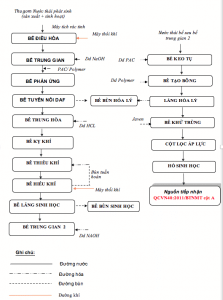

Technology diagram of rubber wastewater treatment

Explanation of rubber wastewater treatment system

Wastewater from unit projects (domestic activities and from the factory’s rubber processing activities, etc.) is collected through the wastewater drainage system and flows into the wastewater treatment system.

Pre-treatment

Preliminary treatment cluster includes: Collection tank à Garbage separator à Conditioning tank

Collecting tank

Before entering the collection tank, wastewater is removed from large-sized trash using coarse trash screens to protect the pump and pipeline system. The collection tank is the place to receive domestic and production wastewater.

Air conditioning tank

Before entering the equalization tank, wastewater is removed from trash through a fine trash separator to protect the pump and pipes behind. The conditioning tank has the function of regulating the flow and concentration of pollutants in the system to avoid microbial shock.

Physicochemical treatment – flotation

Physical and chemical treatment cluster – flotation includes: Intermediate tank ->Reaction tank ->DAF flotation tank

Intermediate tank

Wastewater is pH balanced through a NaOH filling system to ensure high flocculation efficiency.

Reaction tank

PAC coagulant chemical is added and mixed well. Coagulants help destabilize “colloidal” residue particles and stimulate them to coalesce with other suspended residues to form flocs.

A. Polymer flocculation aid will be injected. A. This polymer has the effect of binding the flocs together to form larger sized flocs to improve the efficiency of pollutant removal.

DAF flotation tank

Air is dissolved under pressure into the wastewater and pumped directly into the flotation tank. After entering the tank, air pressure is created and combined with water, will be saturated with air bubbles smaller than 100 microns in size. Tiny air bubbles create a specific gravitational force that adheres to solid particles suspended in water and lifts the suspended particles to the surface of the liquid, forming a layer of floating sludge that is removed by the filter. scratch the surface.

Biological treatment

Biological treatment cluster includes: Anaerobic biological tank à Anoxic tank à Aerotankà Biological sedimentation tank

Anaerobic tank

Nutrients are added to the tank. Wastewater is distributed into the tank and moves through the suspended anaerobic sludge layer. Here, the process of decomposition of organic substances takes place under the action of microorganisms in the absence of oxygen. In addition, the Phosphorus processing process also takes place with the participation of the AOPs bacterial group. Biological phosphorus release occurs through the development of AOPs that are dependent first on anaerobic and then aerobic conditions. Under anaerobic conditions, bacteria break down high-energy bonds in stored polyphosphate chains, resulting in phosphate release accompanied by consumption of biodegradable organic matter.

When microorganisms belonging to the AOPs group from the anaerobic biological tank are introduced into the aerobic biological system, they capture phosphate (PO4)3- and form polyphosphate molecules inside the cell, so the phosphorus content in the system will gradually decrease. When microorganisms are disposed of (excess sludge), this accumulated phosphorus is also eliminated.

Anoxic Tank

Wastewater is adjusted to optimal pH by pouring NaOH alkaline solution on the pipe before leading into the Anoxic tank. Under anoxic conditions, heterotrophic microorganisms develop to process N and P more thoroughly through the process of Nitrate and Phosphoril reduction. To give microorganisms maximum contact with the substrate source and avoid sedimentation, stirrers will be installed in the tank to ensure mixing. In the Anoxic tank, thanks to the sludge return line from the intermediate sludge tank to the reflux pump system, it carries oxygen and helps maintain a stable amount of microorganisms in the tank, creating favorable conditions for anoxic microorganisms to grow. development, while increasing the flow retention time, helping the denitrification and phosphorus removal process.

The BOD treatment process takes place simultaneously with the Nitrogen and Phosphorus reduction process at the ratio BOD:N:P = 100:5:1. Thus, when reducing 5 nitrogen molecules and 1 phosphorus molecule, 100 BOD molecules will be consumed. Anoxic microorganisms will decompose and convert BOD into CO2, water.

The process of denitrification occurs as follows:

The two main strains of bacteria involved in this process are Pseudomonas and Clostridium. In an oxygen-deficient environment, these bacteria will reduce Nitrate (NO3–) and Nitrite (NO2-< /sup>) according to the metabolic chain: NO3– → NO2– → N2 O → N2↑. The formed molecular nitrogen gas N2 will escape the water and go outside. So the nitrogen has been processed.

Aerotank

Aerotank tanks operate based on aerobic activated sludge treatment in the entire tank volume. Air is supplied into the tank through the air distribution system at the bottom to facilitate mixing of activated sludge and wastewater. Microorganisms use the supplied oxygen to consume organic pollutants in wastewater.

In the aerobic tank, two main processes occur as follows:

Nitrification process:

The nitrification process from Ammonium Nitrogen is divided into two steps and involves two types of microorganisms, which are Nitrosomonas bacteria and Nitrobacteria. In the first step ammonium is converted to nitrite and in the second step nitrite is converted to nitrate

Step 1. NH4– + 1.5 O2 –> NO2– + 2H+ + H2O

Step 2. NO2– + 0.5 O2 –> NO3–

Nitrosomonas bacteria and Nitrobacteria use energy from the above reactions to sustain themselves and synthesize biomass. The process can be summarized by the following equation:

NH4– + 2 O2 → NO3– + 2H+ + H2O (*)

New biomass synthesis process:

Oxidation and decomposition of organic matter:

Organic matter (BOD) + O2 → CO2 + H2O + energy

The process of synthesizing new cells:

Organic matter (BOD) + O2 + NH3 → Microbial cells + CO2 + H2</ sub>O + energy

Endogenous decomposition process:

C5H7O2N + O2 → CO2 + H 2O + NH3 + energy

The entire oxidation and synthesis reaction is shown by the following reaction:

NH4+ + 1,83O2 + 1,98 HCO3– –> 0,021C5H7O2N + 0,98NO3– + 1,041H2O + 1,88H2CO3

The amount of oxygen needed to oxidize ammonium to nitrate requires 4.3 mg O2/ 1mg NH4+. This value is close to the value 4.57 commonly used in design calculation formulas.

In addition, to avoid biological sludge loss and increase nitrogen treatment efficiency, the sludge return process from the aerobic tank to the anoxic tank is carried out using a circulating pump system located in the Aerotank tank.

Biological sedimentation tank

Wastewater after biological treatment contains a lot of microbial sludge. Therefore, it is necessary to separate them from the water before going through the next treatment process. The sedimentation tank is designed to separate microbial sludge flocs from treated water by gravity sedimentation process.

The settling tank is divided into 3 parts: clear water part, settling part and sludge part.

Water is fed into the central pipe and from there distributed evenly throughout the tank. Under the influence of gravity and the barrier, the microbial sludge flocs settle to the bottom, and the clear water moves up. The clear water will be collected through the overflow trough system and continue to flow to the intermediate tank.

The sludge settles at the bottom of the tank, a part of the sludge is circulated back to the first level Anoxic tank and a part will be pumped into the sludge tank for compression.

In addition, the sedimentation tank is designed with a suitable beveled angle and the mud scraper is arranged to remove the sludge to the collection center in the center of the tank, helping the bottom sludge collection process take place thoroughly, avoiding the situation of sludge floating on the surface. a situation that frequently occurs in biological systems.

Wastewater after the settling tank is led through the physicochemical cluster (for backup use when the output water is not satisfactory).

Secondary physicochemical treatment

Intermediate tank à Flocculation tank à Flocculation tank à Physicochemical sedimentation tank

The physicochemical cluster has a backup function in case wastewater contains high levels of pollutants and exceeds the load-bearing capacity of the biological system ahead. Then the wastewater will be pumped from the intermediate tank through the physicochemical cluster to continue the reaction process.

The task of the coagulation – flocculation tank is to settle sediment particles with a size of less than 10-4 mm or colloidal particles by introducing flocculating agents into the liquid. The effect of breaking down colloidal particles or adsorbing small particles onto its surface or sticking small particles together.

Physical and chemical sedimentation

The physicochemical sedimentation tank is designed to remove sediment particles in the water by gravity according to the continuous flow into the tank and out of the tank.

The water in the tank moves from the center of the tank to the sawtooth trough.

Finishing treatment

Disinfection tank->Pressure filter column-> Biological lake

Disinfection tank

Responsible for storing water and disinfecting it to kill disease-causing microorganisms. Chemicals used to disinfect wastewater are chlorine compounds.

NaOCl is a commonly used disinfectant due to its high bactericidal efficiency and relatively cheap price that will be used for this project. The water disinfection process occurs in two stages: first, the disinfectant diffuses through the microbial cell envelope and then reacts with enzymes inside the cell and destroys the metabolic process leading to microorganisms. be destroy.

Pressure filter column

After passing through the pressure filter column, wastewater will be thoroughly treated of remaining suspended solids (TSS) in the wastewater and adsorbed and thoroughly treated part of the remaining color in the wastewater.

The output water meets Column A, QCVN 40-MT: 2011/BTNMT_National Technical Regulations on industrial wastewater before being put into the region’s general wastewater system.

Sludge treatment

Biological sludge

During the initial period, when the density of microorganisms has not stabilized or during the operation process, when microorganisms are replanted, the amount of sludge deposited at the bottom of the tank will be circulated almost 100% to the anoxic biological treatment tank. In stable times, the recirculated sludge accounts for about 90-95% of the sludge produced, only about 5-10% of the sludge pumped to the biological sludge tank.

Physicochemical mud

Will be pumped and stored in the physical and chemical sludge tank according to regulations

Physicochemical sludge and biological sludge will be supplemented with C. Polymer sludge decompression aid and put into the sludge dewatering machine. The pressed sludge is collected and processed by waste treatment units or used as fertilizer in the agricultural industry.

Nam Viet ETC is a unit that has a lot of experience in constructing water treatment systems that meet standards and bring efficiency. economic results for Customers. If you need advice or design a quote, please contact us for more detailed support. Hotline 0932562177

Related articles

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...