Odor treatment is widely applied in many industrial fields such as in barn odor treatment systems, landfill odor treatment systems…

Effects of odors.

- Causes discomfort that directly affects the health and feelings of the operator,

- Causes discomfort and makes the company’s landscape and campus look ugly

- In particular, if a foul odor arises from the operating system, it can be a sign that the system is having problems and affects the quality of output wastewater.

Cause of bad odor.

- Bad odors arising from septic tanks or septic tanks: NH3, H2S, CH4..

- Bad smell arising from the saturation tank: H2S, CH4

- Bad smell arises from the biological tank cluster

- The smell of chemicals used in wastewater treatment.

- Bad odors arise from sludge tanks and sludge and wastewater treatment processes: NH3 and H2S

Methods to treat odors

Methods to control odors arising from wastewater treatment systems include the following series of measures:

- For wastewater with a foul odor, the wastewater collection system must be sealed, with odor-preventing rabbits installed at wastewater generation points.

- Calculate the appropriate amount of aeration into the conditioning tank and biological tank cluster to ensure that no anaerobic process takes place here.

- For septic tanks, there should be a ventilation system. In case it is near a wastewater treatment system, there should be a gas collection line to the common odor treatment system for the wastewater treatment system.

- There should be a separate, well-ventilated area to store chemicals, covered with a roof to avoid uncontrolled odors

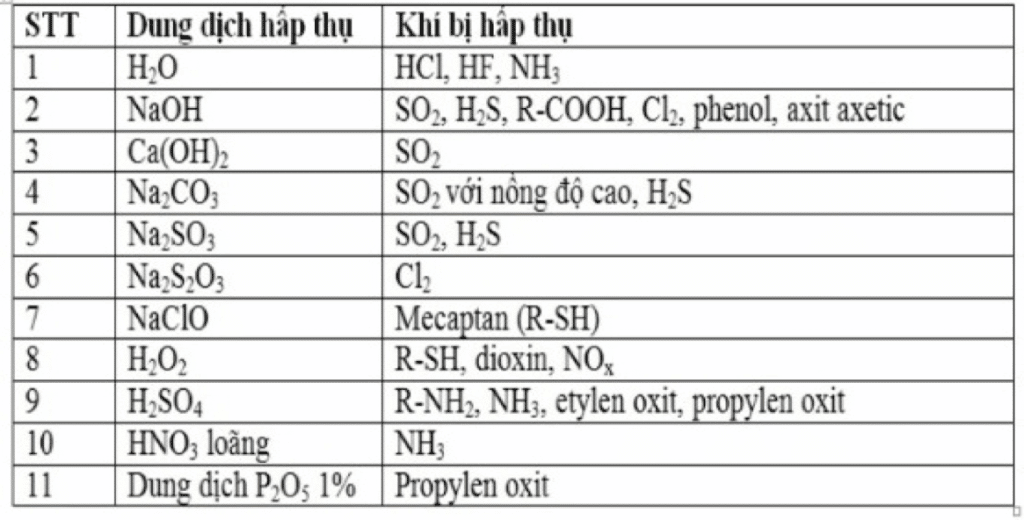

- Gas absorption is the process of transferring the gas components that need to be treated into the liquid phase through the dissolution process when they come into contact with each other. The solutions used in this method are usually water or dilute organic and inorganic solutions, called absorption solutions. The polluted gas is called the adsorbent.

There are 2 types of absorption:

- Physical absorption: During the absorption process, no chemical interaction occurs, physical absorption is a reversible process.

- Chemical absorption: During the absorption process, a chemical reaction occurs.

With the process of absorbing and treating polluted gases, chemical absorption is especially convenient because of its sustainable bond.

Exhaust gas treatment by absorption method is a gas separation process based on the affinity of some solids for certain gases present in the gas mixture in general and in the exhaust gas in particular.

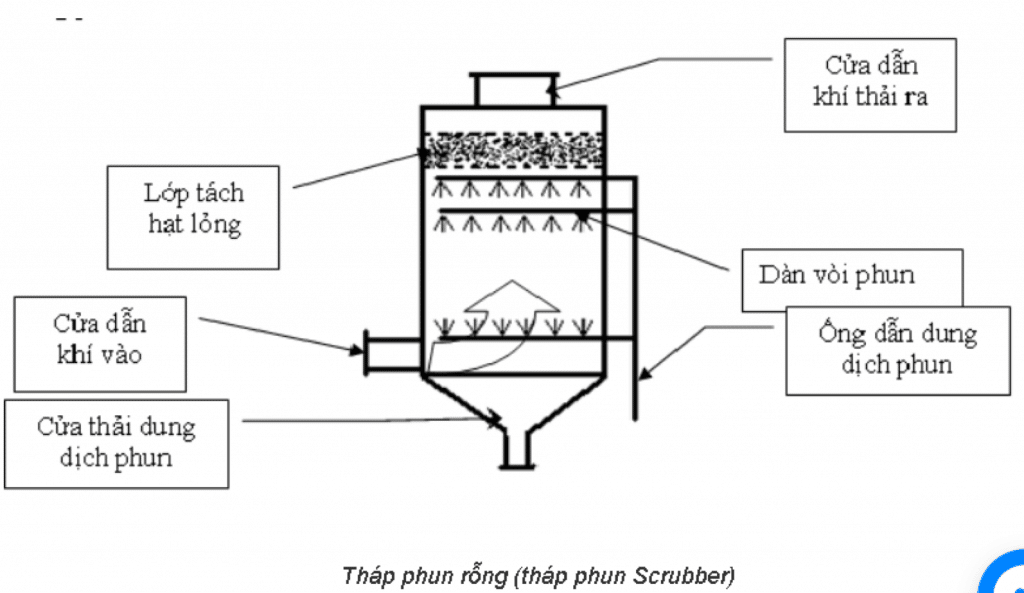

Wet Scrubber has the following forms:

- The tower is empty

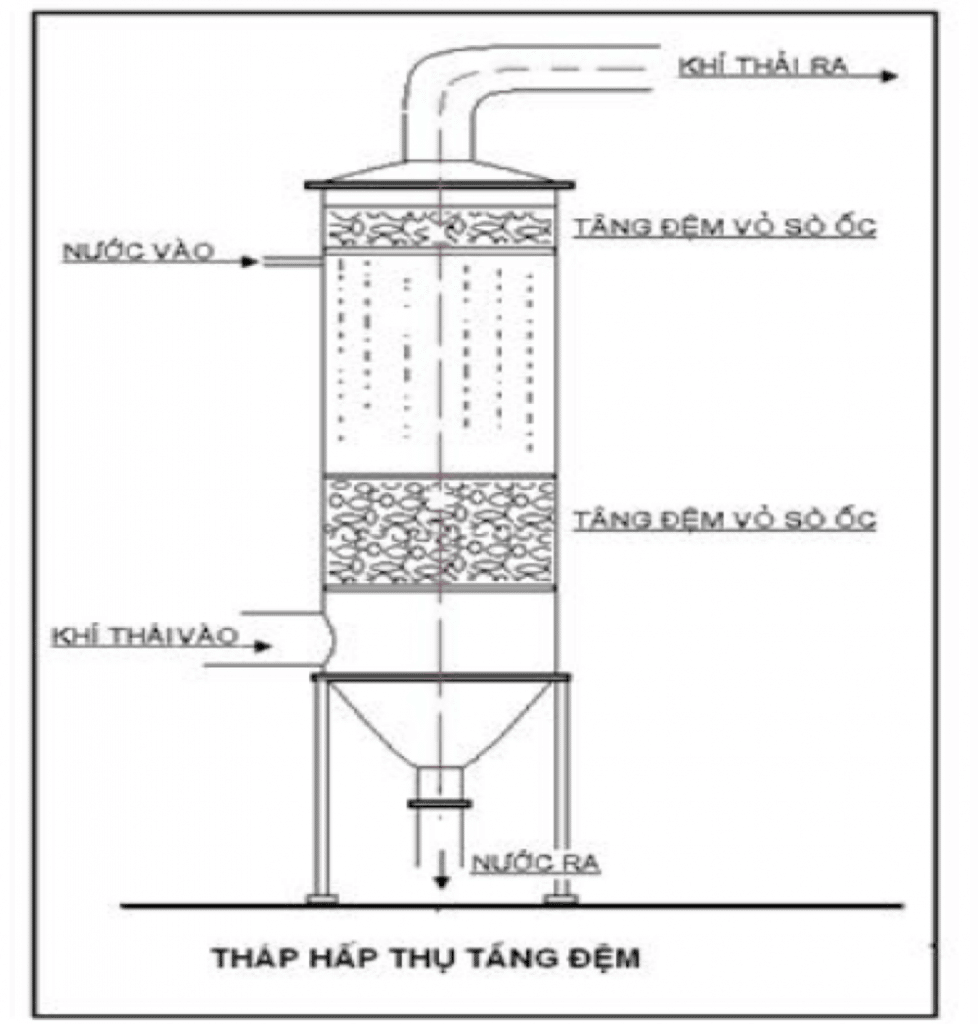

- Buffer tower

- Lattice dish tower

- Spray tower

- Bubble tower

- Venturi tower…

The absorption tower is used to filter toxic gas containing very little dust to avoid clogging the mattress layer. The air flow rate through the cushion layer is designed to avoid choking in the cushion layer. In practice, people often combine spray chambers and buffer towers to filter toxic gas. Equipment of this type has a spray chamber at the top and a buffer tower at the bottom.

When discharged from the bottom up through the buffer tower and through the spray chamber, it is then passed through another layer of hollow material to separate the spray water particles.

The air flow velocity passing through the cushion layer is in the range v=1~1.5 m/s. Buffer layer thickness h = 0.4~3 m. The absorbent solution is distributed evenly over the entire cross-section of the tower by nozzles or drilled pipes.

Irrigation intensity of absorption solution μ = 1.5 ~ 4 kg/kg kk. Tower resistance for exhaust gas flow p = 60 x (h/0.4) kg/m2.

Gases absorbed when using an absorption tower:

Advantage:

- High efficiency, especially for gases with good solubility.

- Can handle low temperature and high flow gas.

- Simple to operate, easy to maintain and repair.

- Absorbent solution is easy to find and can be reconstituted.

- Gas treatment can be combined with dust separation and refrigeration

Defect:

- If reconstitution is used, there is a cost to reconstitute the solution.

- If not reconstituted, wastewater must be treated.

- Waste energy.

- Space occupation.

Buffer materials to handle odors:

Buffer material is the main component of the filler layer used in absorption towers.

The padding is cushioning materials such as Raschig rings or else it can be a specially designed structural material. The buffer material can also be catalyst particles or zeolite pellets, granular activated carbon,…

The bedding material layer is filled with randomly placed bedding material (random bedding layer). Or with padding materials arranged or stacked on top of each other (stacked padding). Shape, surface area and porosity of the cushion material. These are factors that affect processing performance.

Types of cushioning materials used to treat odors

Cushion materials on the market come in sizes from 3mm to about 75mm, porosity (about 65-95%). It is a good sealing material because it allows a large amount of fluid to come into contact with the exhaust gases as it passes through the sealing layer. In addition, the high porosity of the buffer materials will reduce the resistance to the absorption process.

There are three types of cushioning materials:

Ceramics: high humidity, corrosion resistance at high temperature, poor durability.

Metal: Outstanding durability but heavy weight and high cost.

Plastic: good durability, but poor wettability at low, cheap fluid levels.

Raschig ceramic ring and saddle rings are used infrequently. Because they are old cushion materials, the cost is relatively low and the treatment efficiency is not high.

Pall Ring made of plastic or metal and have a clearness of 90% to 96%. This cushioning material was much more effective and is still used today.

Intalox cushioning material The newest tab is a combination of a saddle ring and a Pall ring.

Odor Treatment Consulting Ks Hoang Tuan – 094 1107997

Related articles

Nam Viet Environment Company cleans up beach trash to spread the message of environmental protection

No one alone can litter a pile of trash. Anyone who sees trash criticizes it,...

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...