Food processing wastewater has very diverse characteristics in terms of composition and pollution concentration. Depending on the type of food, Nam Viet ETC factory will have design technology is appropriate.

Sources of food processing wastewater

- The initial food processing process such as selecting and cleaning ingredients

- Product processing

- Cleaning processing machinery and equipment, cleaning production factories…

- Wastewater generated from daily activities, cleaning, and bathing of workers and employees

- Wastewater generated from the factory’s cooking and dining areas…

Food processing wastewater arises mainly from the preliminary processing stage

Properties of food processing wastewater

Due to the specific characteristics of the food production industry, it is very diverse in input materials of different factories such as: Instant noodle production, nutritional porridge production, fast food, milk and dairy products, Wine and vegetable oil production, meat and seafood processing, canned food processing, etc. So the properties of wastewater are also very diverse:

- Contains high levels of Nitrogen and Phosphorus

- The concentration of TSS, BOD, COD, and bacteria components is quite high

- Some types of food wastewater contain salinity, color, and starch

- Has relatively large and stable traffic

- Contains organic compounds (usually less toxic) originating from animals and plants

- Organic waste originating from plants is mainly carbohydrates

- Waste of animal origin is composed mostly of protein and fat

Table of pollution parameters of food processing wastewater

| T | Parameters | Units | Input value | QCVN 40:2011/BTNMT | |

| Column A | Column B | ||||

| 1 | PH | – | 6.5 – 8.5 | 6 – 9 | 5.5 – 9 |

| 2 | BOD5 | mg/l | 700 – 2000 | 30 | 50 |

| 3 | COD | mg/l | 1000 – 3500 | 75 | 150 |

| 4 | TSS | mg/l | 350 – 700 | 50 | 100 |

| 5 | Total Nitrogen | mg/l | 100 – 350 | 20 | 40 |

| 6 | Total Phosphorus | mg/l mg/l | 30 – 100 | 4 | 6 |

| 7 | Grease | 50 – 200 | 5 | 10 | |

| 8 | Total Coliform | MPN/100ml | 104– 105 | 3,000 | 5,000 |

Commonly used food processing wastewater treatment technology

Regarding the complex and diverse nature of food wastewater, there is no specific treatment process, but depending on the wastewater characteristics, NAM VIET ETC will propose appropriate treatment technology.

- For vegetable, fruit and food production wastewater with low N concentration, high BOD, grease and suspended sediment, it is often applied with Flotation – Aerobic technology, which can be combined with further filtration. contact.

- For wastewater from production industries such as fast food, seafood, fish ball – beef ball processing, sausage – sausage… containing high CHC, nitrogen, grease or high residue is often treated. Using flotation technology – Anaerobic – Anoxic – Aerobic.

- For wastewater with high CHC, N or grease and low residue, with limited construction area such as the fish sauce processing industry, the technology of Grease Separation – Anaerobic – Anoxic – Aerobic MBBR is often applied. , combined with pressure filtration.

- In some food processing industries with high pollution parameters such as: livestock slaughtering, fish sauce processing… it can be combined with physicochemical treatment methods such as flocculation, flocculation, flotation DAF and pretreatment by mechanical methods such as: fine trash screen, sand settling tank…

Food processing wastewater treatment system

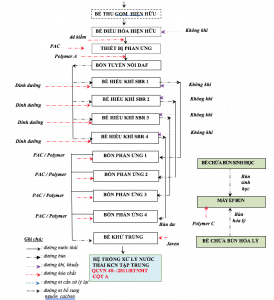

Technological diagram of food processing wastewater treatment

Nam Viet food processing wastewater treatment technology diagram designed for customers

(Depending on the actual needs and characteristics of wastewater, it can be changed accordingly)

Preprocessing

Collecting tank

- Before entering the collection tank, wastewater is removed from large-sized trash using coarse trash screens to protect the pump and pipeline system.

- The collection tank is the place to receive domestic and production wastewater from the factories in the factory.

- Here, wastewater is pumped through the equalization tank using a submersible pump.

- The wastewater pump operates alternately in 2 modes: AUTO and MAN.

- The float is connected to the sump pump to signal when the tank is full or empty

- Before entering the collection tank, wastewater is removed from trash through the existing trash separator to protect the pump and pipes behind

Air conditioning tank

- The air conditioning tank has the function of regulating the flow and concentration of pollutants in the system to avoid microbial shock.

- Water will then be pumped into the high-speed spiral rig device with 2 submersible pumps to start the physicochemical treatment – flotation cycle.

- Two wastewater pumps operate alternately in two modes: AUTO and MAN.

- The float is connected to the conditioning tank pump to give a signal when the tank is full or empty6.2 Physicochemical treatment – flotation

Physical and chemical treatment cluster

High-speed torsion gantry

- Wastewater is pH balanced through the NaOH filling system to ensure high flocculation efficiency.

- After that, PAC coagulant chemical is added and mixed thoroughly thanks to the pump’s thrust and the movement of water in the tube.

- Coagulants help destabilize “colloidal” residue particles and stimulate them to coalesce with other suspended residues to form flocs.

- Coagulation aid A. Polymer will be injected. A. This polymer has the effect of linking the flocs together to form larger flocs to improve the efficiency of pollutant removal.

- Wastewater from the high-speed spiral rig will be led through the flotation tank.

Floation tank

Air is dissolved under pressure into the wastewater and pumped directly into the flotation tank. After entering the tank, air pressure is created and combined with water, will be saturated with air bubbles smaller than 100 microns in size. Tiny air bubbles create a specific gravitational force that adheres to solid particles suspended in water and lifts the suspended particles to the surface of the liquid, forming a layer of floating sludge that is removed by the filter. scratch the surface. This amount of boards is transferred to the physicochemical sludge tank

Biological treatment cluster

SBR batch aerobic tank</span >

SBR tanks operate in a cyclic cycle with 5 phases including: Filling, aeration, settling, draining and resting.

- Filling phase: Wastewater is pumped into the treatment tank for about 1-3 hours. In the reactor, which operates in successive batches, depending on the treatment goals and input BOD content, the filling process can change flexibly: Filling – static, filling – mixing, filling – aeration.

- Aeration phase: Aerate the treatment tank to create a biochemical reaction between wastewater and activated sludge or aerate the surface to supply oxygen to the water and stir the mixture evenly. Ventilation time depends on wastewater quality, usually about 2 hours.

- Sedimentation phase: Sedimentation in water. The process takes place in a static environment, the tank’s hydraulic efficiency reaches 100%. The time for settling and concentrating the sludge usually ends 2 hours earlier.

- Water withdrawal phase: About 0.5 hours.

- Waiting phase: Waiting to load a new batch, waiting time depends on operating time.

- In the SBR aerobic tank the following processes occur:

- Nitrification process:

The nitrification process from Ammonium Nitrogen is divided into two steps and involves two types of microorganisms, which are Nitrosomonas bacteria and Nitrobacteria. In the first step ammonium is converted to nitrite and in the second step nitrite is converted to nitrate

- Step 1. NH4– + 1.5 O2 –> NO2– + 2H+ + H2O

- Step 2. NO2– + 0.5 O2 –> NO3–

Nitrosomonas bacteria and Nitrobacteria use energy from the above reactions to sustain themselves and synthesize biomass. The process can be summarized by the following equation:

NH4– + 2 O2 → NO3– + 2H+ + H2O (*)

New biomass synthesis process:

- Oxidation and decomposition of organic matter:

Organic matter (BOD) + O2 → CO2 + H2O + energy

- The process of synthesizing new cells:

Organic matter (BOD) + O2 + NH3 → Microbial cells + CO2 + H2</ sub>O + energy

- Endogenous decomposition process:

C5H7O2N + O2 → CO2 + H 2O + NH3 + energy

The entire oxidation and synthesis reaction is shown by the following reaction:

NH4+ + 1.83O2 + 1.98 HCO3– –> 0.021C5H7O2N + 0.98NO3– + 1.041H2< /sub>O + 1.88H2CO3

The amount of oxygen needed to oxidize ammonium to nitrate requires 4.3 mg O2/ 1mg NH4+. This value is close to the value 4.57 commonly used in design calculation formulas.

Biological sedimentation process

- Under the influence of gravity, microbial sludge flocs settle to the bottom, clear water moves up. The clear water will be collected by a tank surface water pump

- Sludge that settles at the bottom of the tank is pumped into the sludge tank for compression.

- The wastewater after the settling tank is surface pumped through the secondary physicochemical treatment tank cluster

Second order physicochemical cluster

Physicochemical reaction tank

- Adjust pH to stabilize wastewater into the tank

- Depositing of sediment particles smaller than 10-4 mm or colloidal particles by adding flocculating agents to the liquid that break up the colloidal particles or adsorbs small particles to its surface or sticks small particles together.

- Facilitate contact between flocculating and flocculating chemicals and sediment particles in wastewater. and keep the residue particles from breaking apart

- Deposit the physicochemical residues and clean water will be recovered on the surface to thoroughly treat pollutants COD, Nit, phosphorus, TSS and remaining pollutants in wastewater

- Clean water will go up to the top of the reaction tank through the disinfection tank.

Finishing treatment

Disinfection tank

- Disinfection tank is responsible for storing water and disinfecting to kill disease-causing microorganisms. Chemicals used to disinfect wastewater are Javen ‘s compounds

- NaOCl is a commonly used disinfectant due to its high bactericidal efficiency and relatively cheap price that will be used for this project.

- The water disinfection process occurs in two stages: first, the disinfectant diffuses through the microbial cell envelope, then reacts with enzymes inside the cell and destroys the metabolic process, leading to microorganisms are destroyed.

- Output water meets Column B, QCVN 40-MT: 2011/BTNMT_National technical regulations on industrial wastewater before being put into the centralized wastewater system of industrial parks

Sludge treatment

- Sludge generated during physicochemical and biological treatment will be sent to the sludge tank.

- Here, the physicochemical sedimentation sludge and biological sludge will be supplemented with C. Polymer sludge decompression aid and put into the sludge dewatering machine.

- The pressed sludge is collected and processed by waste treatment units according to regulations

Food processing wastewater treatment system by Nam Viet ETC builds and always commits to:

- Survey, design, construction, supply and installation of technological equipment and technology transfer to ensure that the wastewater treatment system can operate stably with designed capacity and meet technical regulations National industrial wastewater QCVN 40:2011/BTNMT

- Advanced technology, simple operation, reasonable investment and operation.

- High processing efficiency and stability

- Costs for investment, construction, operation and maintenance are relatively low

- Suitable for wastewater with low to high COD content

- The devices are relatively simple and take up little space

- The plant’s processing capacity can be increased when necessary

- Does not cause environmental pollution during operation

- After-sales care policy with many preferential services

Nam Viet ETC – a unit with extensive experience in constructing food wastewater treatment systems that meet required standards and bring economic efficiency to customers.

Please contact us for free consultation on food technology, design plans – Quotation. Hotline 0932562177

Bài viết liên quan

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...